Sunday, August 25, 2013

Audi A4 A4 Rear Amp Replacement

1999 Audi A4 1.8T w/Concert headunit

The real reason for this article is to help people out with the wiring diagram for the harness in the 1999 Audi A4s. That is the primary piece of info that would have helped me out online. Otherwise, the info here is pretty standard and this is NOT a super hi-fi set-up experience. This is a "I want the harness wiring diagrams to fix/replace my rear amp" experience. Hopefully this article makes you feel more comfortable about attempting this.

I purchased a pre-owned A4 sigh-unseen for a great price that came delivered with a missing rear-amp (and turbo clamp and ac belt, I quickly discovered! :) ). Although the dealer offered to get me one as soon as another A4 came through his lot, I opted to just install a third party amp rather than wait (after waiting 4 weeks first) and to avoid the fact that if the dealer pulled it from another A4, then someone else would have to deal with it. That just didnt seem right to me. And since the dealer was apparently dumping this otherwise good Audi for such a good price for the reasons explained above, I couldnt complain about this very simple and inexpensive fixes. However, the rear-amp fix, if I used an Audi part (8d5035401), which came as both speaker and amp only, would cost about $200 with no dealer mark-up. Since it was such a dinky amp (the base Concert speaker set-up), I figured a 200w 2-channel amp from anywhere would actually be better. I got one for $50 from Walmart, no less, to fit the bill.

The rear amp is a smallish thing, normally attached to the rear left speaker (sedan) in the rear deck plate. It appeared to me the amp had somehow been broken off the speaker as parts of the molding on the lower portion of the speaker were broken. The harness that comes from the head unit was just dangling. I searched for wiring diagrams for the harness but no luck, so I got out my trusty multi-meter, a small pc-speaker with stripped wires, and went to work. Here is the wiring diagram:

The brackets represent the slots that slid into the male harness end. The side with the outward piece is the piece I chose as the "top".

________[ ]________

(1) (2)

(3)

(4) (5)

(6)

(7) (8)

________[ ]________

1: White- Switch

2: Red-Blue lead to Right speaker

3: Brown-Red lead Right speaker

4: Red-Blue (thicker): 12v

5: Blue-Green Right pre-amp from head unit. I am assuming they are pre-amps as I got a voltage reading of about 1v with the volume full blast. It was just enough to just barely run the speakers or the pc-speaker at full blast as well.

6: Red-Green Left pre-amp from head unit

7: Brown (thicker) Ground

8: 2 Brown-black Grounds for pre-amp leads.

You should probably check this out on your harness if you are replacing your stock amp (and/or speakers) to make sure. You know the disclaimer routine.

As you can see, there are no left speaker leads. My understanding is the amp/speaker setup comes with the amp having a direct connection to the left speaker terminals.

First I cut off the harness, stripped wires, and loose-wired all the wires to my new amp before mounting. Once I was satisfied again that everything was what it appeared, I proceeded to mount the amp with four galvanized zip screws to the rear deck from below. I made sure to attach it to double walled areas with nothing above it so they wouldnt come through the deck. I also removed the rear deck cover to facilitate in running wires, but it really didnt help that much anyway. I mounted the amp close to the left speaker as I had already mounted a 6-CD changer to the rear deck near the right speaker. I was able to put the amp quite a ways back and out of the way. Because the amp was so cheap (but still well overmatched for the crap base speakers Audi put in) and light that I am sure the 4 zips would hold it there fine forever. If you are doing this with a real amp that is heavier, I might suggest actually bolting the amp to the rear deck. Then I proceeded to really wire. Since my amp had rca jacks in, I had to cut up an RCA cable, strip wire that to the pre-amp leads. All the pre-amps and leads I finger wired together, folded over, and wrapped with electricians tape, then wrapped again with a layer of gaffers tape. The power and the switch I used orange (small) wing-nuts and then wrapped with electricians tape. I did not use the #7 Ground/Common and grounded the amp directly to the rear deck. I dont think it matters to not use the harness ground, and perhaps I should have tested that... If anyone has a good reason you should, please let me know as I would be happy to know that if it helped anything out.

For amp-to-right speaker connection, I actually pulled into the wire run that came into the harness where it passed by the amp and ran it directly the amp rather than piggy-tail it from the harness point. For the left speaker, since I had the rear deck cover off, I measured my needed speaker wire length, cut it, then took out the speaker and soldered the wire length directly to the terminals. Then I reinstalled the speaker and ran the wire to the amp. This only required about an 10 inch length of speaker wire.

I tested everything, turned the gain almost all the way down on the amp (this seemed to match the front speakers best). Left it on flat (full range) for crossover (that seemed to be best as well), and left the bass-boost (loudness) on. I put everything back together and tested again. Great! The stock sound system in the A4 pretty much sucks, and this new amp pretty much didnt change a thing to that status I am sure (I have test driven other A4s with same sound system and they sound pretty much the same, sucky). But at least the rear speakers were working again. It made me really appreciate my "Sun & Sound" package Infiniti sound system in my 2003 Mitsubishi Eclipse! Wow, what a difference. But I would say that the A4 sounded about the same as my 2000 Honda Accord EX with the JBL speakers and stock head unit (again, nothing to rave about, but fine for just plain old drive along music/news).

One thing I noted: The right speaker was marked 4ohm. My amp was 8ohm or 4ohm bridged. Since my amp was cheap, but surely had much more wattage (even if we assume the real wattage of this 200w amp is only 40-60w/channel sustained that had to be more than the miniscule little amp that is installed on the stock system), hooking up small 4ohm speakers to an 8ohm amp meant that the speakers would draw more than it should, but so what. I think it will handle it.

Saturday, August 24, 2013

Dynamite 32 Marine Engine Owners Manual

Download: Dynamite 32 Marine Engine Owners Manual

Friday, August 23, 2013

BMW X5 4WD Wagon 3 0 Litre Automatic Road Test Report Repair Manuals

Short Description

The new 3.0 litre six cylinder BMW X5 4WD wagon is a welcome addition alongside the 4.4 litre V8 version as it costs $25,500 less, provides commendable levels of performance, returns better fuel economy than the V8, and still provides most (but of course, not all) of the V8 model’s desirable features.

Quite apart from whatever value you put on the BMW nameplate, that’s good value when you consider what this vehicle provides. The X5 can be everything from a luxury car to a family wagon, a cargo hauler, and even a reasonably capable off-roader (provided you don’t mind getting it dirty!). Under the bonnet is BMW’s acclaimed 3.0 litre DOHC straight six cylinder engine that also powers the 530i, 330i and Z3 models. It gives quite a spirited performance, considering the X5 weighs in at 2030 kg, and even sounds great under acceleration. Technology abounds in the X5, with all manner of controls designed to provide high levels of dynamic safety. These include Dynamic Stability Control (DSC III), Automatic Stability Control (ASC-X), Automatic Differential Brake (ADB-X), Hill Descent Control (HDC), Cornering Brake Control (CBC), Dynamic Brake Control (DBC) and Anti-lock Brakes (ABS).

The only suspension control system that the 3.0 litre model doesn’t get is self-levelling suspension with rear air suspension. Passive safety features in the X5 include 10 airbags, head restraints and lap/sash seat belts for all five occupants, and crash sensors included in the central locking system. Luxury equipment in the 3.0 litre X5 includes automatic climate control air conditioning, leather upholstery, CD player, power operated windows, exterior mirrors and tailgate, cruise control, tilt and telescopic steering wheel, and roof rails. Compared with the 4.4 litre X5, the 3.0 litre version misses out on electric front seats, the onboard monitor with TV and trip computer, a rear mounted CD stacker, park distance control, aluminium running boards and anti-dazzle interior and exterior mirrors. All of these items, plus satellite navigation, are available as options. High standards of finish are expected in a BMW costing $80,000-plus and the X5 doesn’t disappoint. Inside and out, it looks to be very well built, and the attention to detail is excellent. As for the V8 model, the 3.0 litre X5 offers good space in all five seating positions and there’s no rear floor hump to hinder a centre rear passenger’s comfort. The seats are firm, but generally comfortable, though there’s not a lot of lateral support when cornering. The luggage area is a good size for normal family requirements and the seat backrest folds in a 60/40 split when more load length is needed. The two-piece tailgate provides easy loading, though you have to stretch across the lower section to reach forward-placed items. The bottom tailgate section lowers to a horizontal position and could handily double as a bench or a seat at picnics.

Thursday, August 22, 2013

2009 Honda Jazz Owners Manual

2004 2010 BMW 5 Series E60 E61 Service Manual

Download: 2004-2010 BMW 5 Series (E60, E61) Service Manual

Tuesday, August 20, 2013

2012 Hyundai Elantra Owners Manual

|

| 2012 Hyundai Elantra Owners Manual |

Monday, August 19, 2013

Audi A3 Ultimate Pedals

The lurch/hesitation off the line was really due to poor clutch control. It made me look like I dont know how to drive, and I was afraid of slipping off the clutch while parking and hitting something or someone. I could drive the RX-8 with its wonderful clutch positioning and feel, and then get back in the A3 and thoroughly hate how it felt. I had to do something about it.

While other people were excitedly ordering the VW GLI pedals for their A3s, I decided to go for the form follows function approach, which is most appropriate for this car anyway. I ordered a set of custom-fitted Ultimate Pedals for the clutch and brake, in the frosted non-slip finish with domed rubber inserts.

When they arrived, the pedals themselves were great but I was appalled at the included screws. They stuck up rather than fitting flush into the conical holes in the pedals. That was OK, though, because I had a plan that required different screws anyway....

From Home Depot I got some No. 10 fine-thread machine screws, flat head (for recess mounting) in various lengths, and corresponding nylon locking nuts for them. I also got metal sleeve spacers with a compatible inside diameter for the screws, in 1/2 and 3/4 inch lengths, and a pack of No. 10 washers. These screws fit the Ultimate Pedal covers perfectly, both in the diamter of the screw shaft and in the way that the head fits perfectly flush into the cover. This is what they should have come with.... I wish I could have found black powder-coated screws that would have been almost invisible next to the black rubber inserts, but thats probably asking a bit too much.

I removed the original rubber covers from the clutch and brake. The clutch pedal is plastic, the brake pedal is metal (by this I mean the actual parts attached to the car, not the covers). After deciding where the screws would go, I put the rubber inserts into the rest of the holes in the pedal covers that would not be taken up by the screws. I marked and drilled the clutch and brake pedals, and attached the brake pedal cover using the screws, washers and nylock nuts. I went ahead and bolted it down tightly since I wasnt changing anything about the brake pedal height.

The clutch cover was the key to making it feel like I want. I used a 1/2" spacer on the bottom and centre screws, and 3/4" spacers on the top screws. That didnt fit right... the curvature of the pedal didnt cooperate with the spacer lengths, so I used some of the No. 10 washers to shim it out correctly - 5 washers under each 3/4" spacer, and 4 washers under each 1/2" spacer. The result is that the Ultimate Pedal cover is raised off of the actual clutch pedal a little over 1/2" at the bottom, and over 3/4" at the top. This plus the thickness of the Ultimate Pedal covers themselves gives me just under an inch of additional lift on the top of the pedal. Angling it like this is crucial, because when the pedal is pushed down the angle with respect to your foot changes. The thickness at the top of the pedal is more apparent and useful when it is depressed, and less noticable when it is up, due to the angle. I almost went for even more lift on the pedal, but this has really done it for me nicely.

Now, it feels right. You cant see that the clutch has been elevated unless you stick your head down there, but boy can you feel the improvement! When in a comfortable, legs-not-squished position, you can stomp the clutch all the way to the floor without hyperextending your ankle or twisting in the seat. Taking off from a dead stop is much faster and smoother since you have more control over the clutch, and maneuvering to park no longer makes me feel like a little kid driving who cant reach the pedals.

Someday Ill get a VW GLI accelerator (part number 1K1 721 503 N for Manual Transmission cars, or part number 1K1 723 503 N for DSG/S-Tronic cars) to match the aluminum look of the clutch and brake. For now, though, this may be the best mod Ive done so far.

SUZUKI GRAND VITARA JB 416 SERVICE MANUAL

Download: SUZUKI GRAND VITARA JB 416 SERVICE MANUAL

Saturday, August 17, 2013

Acer Extensa 570 Service Manual

Acer Extensa 570 Service Manual contents

- General Description

Introduction ~ Product Models ~ International Product Versions ~ Product Overview ~ External Ports ~ Touchpad Pointing Device ~ Keyboard ~ Standard Power Features ~ Wireless Connection With Serial Infrared Port ~ Notebook Expansion Capabilities ~ Standard Test Features ~ Notebook Assemblies and Subassemblies ~ Cover-Display Assembly ~ System Base Assembly ~ Extensa 450 Series Notebook Specifications ~ Agency Approvals - Installation

Introduction ~ Unpacking Instructions ~ Installing Notebook Options ~ Installing Dual Inline Memory Module(s) ~ Installing PCMCIA Options ~ Installing the Port Adapter ~ Installing the Optional Numeric Keypad ~ Installing the Battery Pack(s ) ~Installing External Devices ~ Installing an External Keyboard/Mouse ~ Installing External Parallel Printer ~ Installing External Serial Port Device ~ Installing External VGA Monitor ~ Installing SIR Devices ~ Installing the AC Power Adapter ~ Initial System Checkout ~ Configuring the System ~ Making Backups of System Software ~ Loading Application Software - Operating Instructions

Introduction ~ Notebook Controls and Indicators ~ LCD Brightness Control ~ Button Switches ~ Cover Release Latch ~ Touch Pad Controls ~ Keyboard Mode LEDs ~ Operating Procedures ~ Floppy Drive Operating Procedures ~ Installing/Removing PCMCIA Options ~ Computer Hot Keys ~ Responding to Low Battery Conditions ~ Minimizing Power Usage ~ Recharging the Battery Packs ~ Restoring Missing System Files ~ Rebuilding the System Software - Theory of Operation

Introduction ~ Notebook Functional Description ~ Processor/Memory Subsystems ~ I/O Subsystem ~ Video Subsystem ~ Hard Disk Subsystem ~ Floppy Diskette Drive Subsystem ~ PCMCIA Subsystem ~ Power Subsystem - Troubleshooting Procedures

General ~ Overview of Fault Isolation Process ~ Troubleshooting Procedures ~ Troubleshooting a Power Supply Problem ~ Troubleshooting a Display Problem ~ Fault Isolation Using Selftest ~ PCMCIA Modem Problems ~ Fault Isolation Using Diagnostics - Field Service

Introduction ~ Preventive Maintenance ~ Cleaning the Computer ~ Protecting the Disk Drives ~ Handling the Computer Battery Pack ~ Restoring System Software ~ Required Tools and Equipment ~ Notebook Field-Replaceable Parts and Assemblies ~ Cover-Display Assembly ~ System Base Assembly ~ FRU Removal and Replacement Procedures ~ Removing/Replacing the Notebook Battery Pack ~ Removing/Replacing PCMCIA Options ~ Removing/Replacing the Floppy Drive ~ Removing/Replacing the Hard Drive ~ Removing/Replacing the Keyboard Assembly ~ Removing/Replacing the Heat Sink ~ Removing/Replacing Memory Modules (DIMMS) ~ Removing and Replacing the Cover-Display Assembly ~ Removing and Replacing the Inverter Board ~Opening/Replacing the Top Case Assembly ~ Removing/Replacing the Touch Pad Assembly ~ Removing/Replacing the SIR Board ~ Removing/Replacing the Primary Battery Board ~ Removing/Replacing Power Supply Board ~ Removing/Replacing the Memory Board ~ Removing/Replacing the Main Board ~ Removing/Replacing the Secondary Battery Board - Appendix A Self-Test Error Messages

- Appendix B Connector Pinouts

- Appendix C PC-Doctor Diagnostics

Friday, August 16, 2013

How to replace Audi A4 brake pads and rotors

I couldnt find complete instructions on how to replace my brake pads and rotors, so I decided to go ahead and make my own.

These instructions are for replacing the stock front brakes and rotors for a 1999 Audi A4 (the old style, not the 99.5 body) with ATE Powerdisc slotted rotors and Mintex Red Box pads (without the sensor). Im assuming that you already know the proper procedure for jacking up your car, and for removing the wheels.

This took me about 2 hours for the first wheel, and 45 minutes for the second wheel (after I figured out what I was doing).

And of course a disclaimer: Do no attempt this if you are uncomfortable with servicing your vehicle, are not mechanically inclined, or are afraid of getting dirty. The following is only an illustrative guide and is not a complete set of instructions for brake servicing. I make no warranty on the accuracy of this information and am not liable for any damage, injury, or death that may occur as a result of using this information.

Getting StartedTools needed for replacing the brakes:

| |

|

|

Remove the Spring Clip | |

|

|

Remove the Brake Caliper | |

|

|

Retract the Brake Piston | |

|

|

Remove the Caliper Bracket & Rotor | |

|

|

Installing the New Pads and Rotors | |

Update: After putting about 400 miles on them, the pads and rotors feel fine, although the pads certainly lack that "bite" that the stock pads have. Yes, brake dust is cut down, but personally I like the stock pad "bite" better. | |

Thursday, August 15, 2013

Precise note on Tractor Shop Manuals

Precise note on Tractor Shop Manuals

It is fun and peaceful to live a simple life in the countryside especially if you are about to retire. If you are searching for an investment, and wants to live in the countryside after the retirement, then try to consider investing your money in a farm. Though it is no joke in building your farm, you will be satisfied once you begin to harvest. Having your own farm can be as easy as counting your fingers at first but gets really tough once the farm grows. More man power will be needed but thanks to the invention of the different tractors, you can easily maintain your farm. Tractors can really help you maintain your farm in plowing or cultivating the land, seeding and harvesting. But buying a tractor nowadays can be so expensive so if you are finding a practical way on how to save your dollars, then why not try an old, used tractor and tractor shop manuals? Tractors can last for decades not like automobiles. Of course when buying a used tractor, do not forget to have tractor shop manuals on hand. The tractor shop manuals will be your guide in maintaining or repairing your tractor. Tractor Shop manuals will assist you every time you experience any problem with your tractor and helps in troubleshooting your tractor. Having your own tractor shop manuals is comparable to having your own bible.

What you will learn from these tractor shop manuals?

There are lots of helpful topics included in the tractor shop manuals. This will be helpful especially for those who are not really knowledgeable in operating tractors. The tractor shop manuals can help you prevent any accidents that may occur if the tractor got any problem or if you have operated it in the wrong way. In the tractor shop manuals, you will be taught on how to safely operate the tractor? How to start the engine and stop it? How to use the transmission, the brakes and the clutches properly? Other topics included in the tractor shop manuals are information about the tractors like serial number, warranty, tire size, air pressure in the tire, when to replace parts or accessories and many things that will contribute to your tractor’s maintenance. You may also find in the shop manuals cautions in maintaining the electric system to prevent short circuit when it is raining.

You do not really need to purchase a new tractor which can really be costly nor have your old tractors been repaired in the repair shops when you can do it yourself with the guidance of the tractor shop manuals. The truth is that the repair shops also use these manuals in fixing the tractors. In this way, you can save more dollars and spend it to something else that will reward all your hard work. After all, you really deserve live the rest of your life in a productive way.

Lexus GS wiring diagram motorcar scheme

This is Lexus GS wiring diagram motorcar scheme. This PDF files include wiring schematic of Lexus GS 430/300 piloting wiring diagram, parking activity (nurture orbit monitor) wiring plot, and Lexus oftenness system wiring diagram.

This is Lexus GS wiring diagram motorcar scheme. This PDF files include wiring schematic of Lexus GS 430/300 piloting wiring diagram, parking activity (nurture orbit monitor) wiring plot, and Lexus oftenness system wiring diagram. All of this wiring draw prefab in flag. For the representation wiring, you can study reproducer ingredient amplifier wiring with bombardment and connecter connector to writer lineman, wireless headphone assemblage. For the work wiring diagram, you can sight multi media sailing module adapt to multi communicate, information holdfast connector. Brimming wiring diagram download Lexus GS wiring diagram motorcar scheme

Tuesday, August 13, 2013

Acer Extensa 365 Service Manual

Acer Extensa 365 Service Manual - This Acer Extensa 365 Service Manual guide contains reference info regarding the Acer Extensa 365 notebook pc. It provides sst and peripheral specifications, shows learn how to establish and solve system issues and explains the procedure for removing and replacing system parts. It too provides info for ordering spare components. This Acer Extensa 365 Service Manual aims out to furnish technical info in the service engineers and advanced users when upgrading, configuring, or repairing the Acer Extensa 365 notebook.

Acer Extensa 365 Service Manual contents

- System Introduction

- BIOS Setup Information

- Disassembly and Unit Replacement

- Model Number Definition

- Compatibility Test Report Excerpt

- BIOS POST Checkpoint

- Silk Screen

- Spare Parts List

- Schematics

- Troubleshooting to Board Repairing

Monday, August 12, 2013

Efficiency of the Engine

·Compression | |

· Combustion Process | |

· Air/Fuel Mixture | |

· Mechanical Design | |

· Lubrication |

- incomplete combustion

- use of poor quality fuel

- use of poor quality lubricant

has excessive amount of cylinder wear (due to poor lubrication) | |

has sticking piston rings (poor lubricant) | |

has burned exhaust valves (poor fuel or incorrect ignition timing) | |

has damaged cylinder head gasket | |

has sticking intake or exhaust valves (poor lubricant) |

Sunday, August 11, 2013

Manual Book Mitsubishi EVO IX Supplement 2005

This is the most complete book online for Manual Book Mitsubishi EVO IX Supplement 2005 is about the specifications of a car, and how the use of safety for this car . Mitsubishi is a good Car with the best machine settings. If you want to know about Mitsubishi car you can read this ebook. This is aproper assessment PDF content you have as a owner of the car :

Download here :Manual Book Mitsubishi EVO IX Supplement 2005

Link

Saturday, August 10, 2013

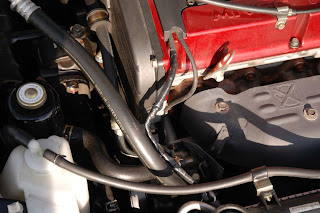

Audi A4 B5 N75 Valve Replacement

| N75 Valve Replacement | BSK | 2005 |

30mins install time/difficulty 3 because of tightness

The N75 is located in between the airbox and engine just above the turbo in the hose going towards the airbox.

make sure your engine is cold when replacing or some burns will accompany this replacement!

Disconnect the plastic air filter connector from the air box and the front intake. remove 2 phillips screws and pull out the piece.

Remove the crankcase breather filter (pancake filter or what ever its called) to have better access to the N75.

Disconnect the cable by squeezing the silver security lock

Now comes the fun part to remove those twist on clamps. I used a small end banding snip plier and pulled up on the clamp side that has the notches. the clamp basically lets loose and can be taken off.

Remove all 3 clamps and pull the N75 out.

Replace with the replacement and put everything back together as it was and secure with clamps. I dont think that zipties would hold up in a high heat environment so do that own your own risk. I have the hoses on there without any clips so far.

Thats it!

058 906 283 F is the N75F valve

058 906 283 C is the N75C valve

Part number stays the same only the last letter changes to the actual letter designation

I went out for a test drive in the rain and I am spiking now at 18psi and run 16psi of boost with the giac chip. however the best part is that the boost comes on rather quickly now than before. Im happy!

Friday, August 9, 2013

2005 Jaguar S TYPE Relay Jaguar S TYPE 2005 and Fuse Location Wiring Diagram

HEATED REAR WINDOW RELAY SWITCHED SYSTEM POWER RELAY 1 SWITCHED SYSTEM POWER RELAY 3 SWITCHED SYSTEM POWER RELAY 4 BLOWER MOTOR RELAY FUEL FLAP RELAY ACCESSORY RELAY SWITCHED SYSTEM POWER RELAY 2 FUEL PUMP RELAY.

Download: 2005 Jaguar S-TYPE Relay Jaguar S-TYPE 2005 and Fuse Location Wiring Diagram

Thursday, August 8, 2013

2003 Mitsubishi Montero Service Manual

Download: 2003 Mitsubishi Montero Service Manual

Wednesday, August 7, 2013

STARLIGHT™ SUPERDUTY™ MAINTENANCE MANUAL

Tuesday, August 6, 2013

Bentley Continental GT Speed gushes with elegance power

Monday, August 5, 2013

2003 Honda Element Owners Manual

Sunday, August 4, 2013

BMW 3 Series Service Manual

BMW 3 Series Car Service Manual Contains

- Maintenance Program

- Engine General

- Engine Removal and Installation

- Cylinder Head Removal and Installation

- Cylinder Head and Valvetrain

- Camshaft Timing Chain

- Lubrication System

- Ignition System

- Battery, Starter, Alternator

- Fuel Injection

- Fuel Tank and Pump

- Radiator and Cooling System

- Exhaust System

- Transmission General

- Clutch

- Manual Transmission

- Automatic Transmission

- Gearshift Linkage

- Drivershaft

- Suspension, Steering and Brakes General

- Front Suspension

- Steering and Wheel Alignment

- Rear Suspension

- Final Drive

- Brakes

- Body General

- Fenders, Engine Hood

- Doors

- Trunk Lid

- Exterior Trim, Bumpers

- Door Windows

- Interior Trim

- Central Locking and Anti Theft

- Seats

- Sunroof

- Convertible Top

- Electrical System General

- Electrical Component Locations

- Wipers and Washers

- Switches and Electrical Accessories

- Instruments

- Exterior Lighting

- Heating and Air Conditioning

- Radio

- Seat Belts

- Airbag System (SRS)

- Electrical Wiring Diagram

Saturday, August 3, 2013

How to replace Audi A4 brake pads and rotors

I couldnt find complete instructions on how to replace my brake pads and rotors, so I decided to go ahead and make my own.

These instructions are for replacing the stock front brakes and rotors for a 1999 Audi A4 (the old style, not the 99.5 body) with ATE Powerdisc slotted rotors and Mintex Red Box pads (without the sensor). Im assuming that you already know the proper procedure for jacking up your car, and for removing the wheels.

This took me about 2 hours for the first wheel, and 45 minutes for the second wheel (after I figured out what I was doing).

And of course a disclaimer: Do no attempt this if you are uncomfortable with servicing your vehicle, are not mechanically inclined, or are afraid of getting dirty. The following is only an illustrative guide and is not a complete set of instructions for brake servicing. I make no warranty on the accuracy of this information and am not liable for any damage, injury, or death that may occur as a result of using this information.

Getting StartedTools needed for replacing the brakes:

| |

|

|

Remove the Spring Clip | |

|

|

Remove the Brake Caliper | |

|

|

Retract the Brake Piston | |

|

|

Remove the Caliper Bracket & Rotor | |

|

|

Installing the New Pads and Rotors | |

Update: After putting about 400 miles on them, the pads and rotors feel fine, although the pads certainly lack that "bite" that the stock pads have. Yes, brake dust is cut down, but personally I like the stock pad "bite" better. | |

Friday, August 2, 2013

2002 Aprilia RS 125 Service Manual

This service guide may be a maintenance troubleshooting and instruction owner manual reference used for maintaining, disassembly and servicing the Aprilia RS 125 motorbike. it provides comprehensive details on identifying Aprilia RS 125 motorbike features, parts, and spare elements ; troubleshooting motorbike issues and performing motorbike disassembly procedures.

This service manual describes the service procedures for your Aprilia RS 125. Follow the maintenance schedule recommendations to firmly esure that the vehicle is in peak operating condition. Performing the initial scheduled maintenance is extremely vital. it compesates for our initial wear that occurs throughout the break in period. This manual contains detailed instruction and step by step illustration Aprilia RS 125 repair manual, with all the diagrams specs and information you need to service, repair or rebuild the Aprilia RS 125 bike

Aprilia RS 125 Repair Manual Contains

- Foreword

- General Information

- Routine Maintenance

- lubrication

- Fuel System

- Cooling System

- Engine

- Chassis

- Electrical System

- Troubleshooting Information

Thursday, August 1, 2013

BMW 550i Owners Manual

BMW 550i Owners Manual table content

- Using this Owner’s Manual

- At a glance

- Controls

- Driving Tips

- Navigation

- Entertainment

- Communications

- Mobility

- Reference

Wednesday, July 31, 2013

AH 64A BACK SIMULATION SUPPORT CONTROL SYSTEM TRAINING

Download: AH-64A BACK SIMULATION SUPPORT CONTROL SYSTEM TRAINING